BURNING/SEPARATION OF THE MATERIAL BY LASER BEAM

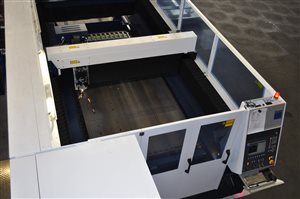

We offer effective processing of iron plates, aluminum and stainless steel, using the most modern computer controlled laser machine TruLaser 3030. It is characteristic by its flexibility and maximum reliability.

Options and method of material´s burning:

1. Burning of dark plates from 1-20mm by oxygen and nitrogen

2. Burning of aluminum plates to thickness 8mm and stainless steel to thickness 12mm by nitrogen

Maximum dimensions of plates 3000x1500mm.

Advantages of material´s separation with a laser beam:

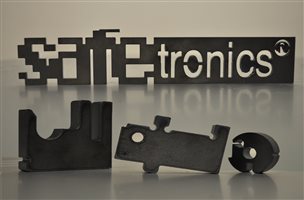

- the burning of any desired shapes according to the technical documentation (shape diversity)

- minimal waste

- high speed

- high flexibility

- maximal accuracy and reliability

- high cutting quality

- plates remain cool/cold

- engraving

- piece or series production

For the fastest realization of your contracts would be appropriate, to send your desired parts in electronic form in formats DXF,DWG, or IPT.In the case of the bent parts, is the most suitable pattern the outspread shape of that part.

For more detailed information, please contact our technical department:

Ing. Michal Trebula

e-mail: trebula@safetronics.sk

tel: +421/907 808 283